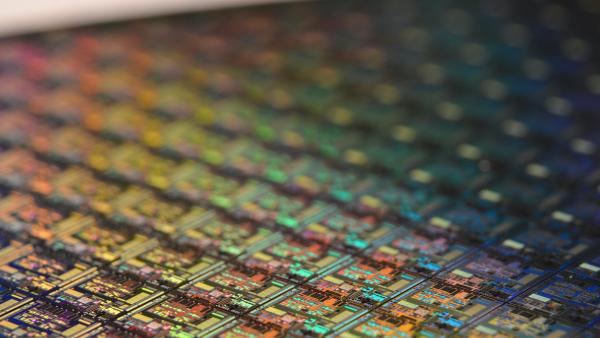

Szeroka gama rozwiązań dla przemysłu elektronicznego

Gazy techniczne i wiedza specjalistyczna z zakresu procesów

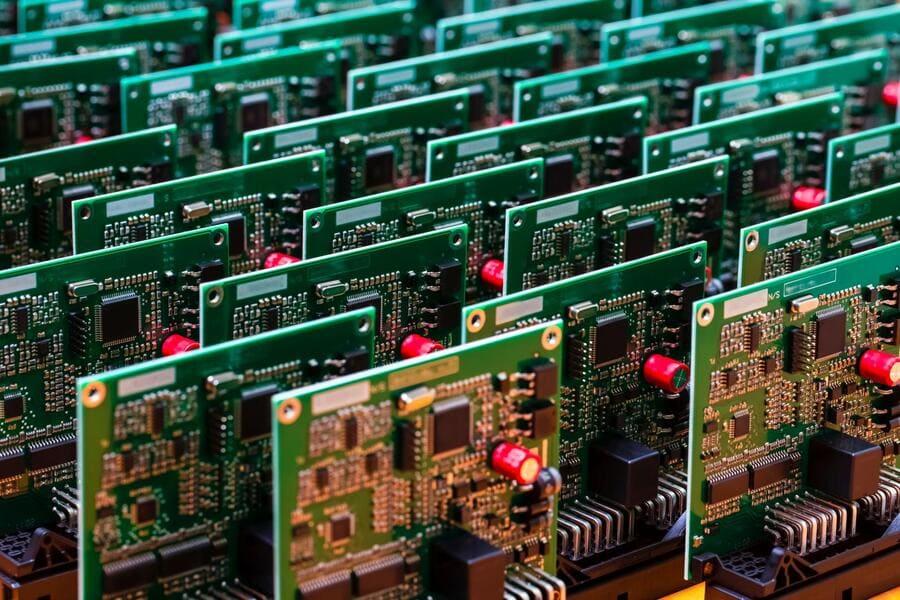

Dzisiejszy przemysł elektroniki wtórnej stoi przed wyzwaniem obniżenia kosztów produkcji, poprawy jakości produktów i wydajności. Jako długoterminowy partner, Air Liquide wykorzystuje swoje doświadczenie i innowacyjne technologie, aby dostarczać bezpieczne, niezawodne i konkurencyjne rozwiązania w zakresie dostaw gazu, które spełniają różnorodne potrzeby przemysłu.

Rozwiązania i dostawy dostosowane do Państwa potrzeb

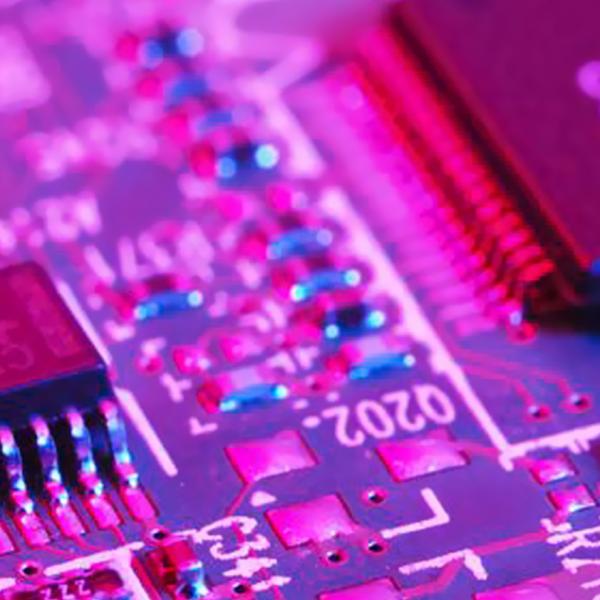

Reakcja utleniania, słaba zwilżalność oraz wysoka temperatura pików podczas lutowania płytek obwodów drukowanych powodują uszkodzenia złączy lutowanych. Aby zrównoważyć te efekty, powszechnie przyjętą praktyką w branży elektronicznej stało się zastosowanie azotu do wytworzenia osłony obojętnej podczas lutowania.

Nasza oferta obejmuje dostawy gazów w postaci ciekłej i sprężonej oraz z jednostek on-site.

Doświadczenie w montażu podzespołów elektronicznych

Montaż podzespołów elektronicznych jest kluczowym procesem. Stąd też oferujemy rozwiązania pozwalające uzyskać kontrolowaną atmosferę azotu, zmniejszając w ten sposób negatywny wpływ utleniania na lutowanie na fali lub rozpływowe.

Nasi specjaliści w technologiach stosowania gazów z przyjemnością pomogą Państwu przeprowadzić próby i znaleźć właściwe rozwiązanie dla Państwa potrzeb.

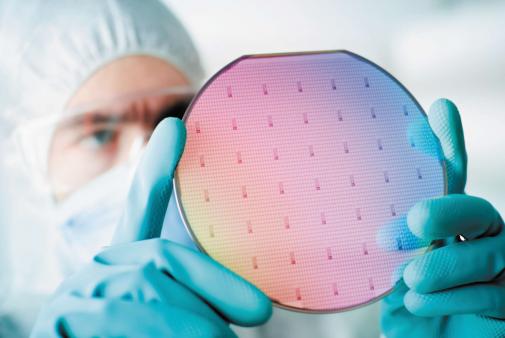

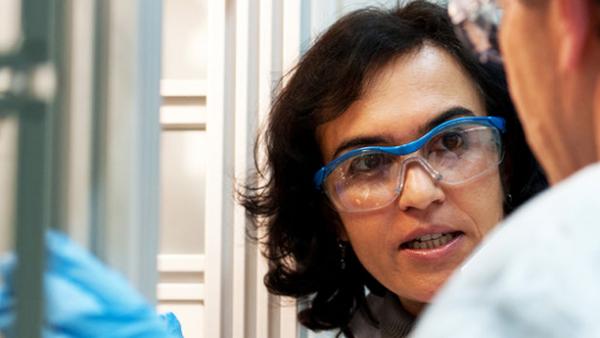

Oferta ekspertów

Air Liquide oferuje innowacyjne i kompletne rozwiązania w dowolnym miejscu na świecie dzięki dedykowanym zespołom - ponad 1500 specjalistów, w tym 70 naukowców w sposób ciągły współpracuje z klientami w ich zakładach.

Jeżeli potrzebują Państwo wsparcia technologicznego czy doradztwa przy rozruchu w celu optymalizacji procesu - nasz zespół doświadczonych specjalistów z branży pozwoli zoptymalizować zużycie gazu i osiągnąć oszczędności.

Rozwój technologii dla przemysłu elektronicznego zapewniają nasze ośrodki badawcze oraz sieć centrów technologicznych rozmieszczonych na całym świecie.